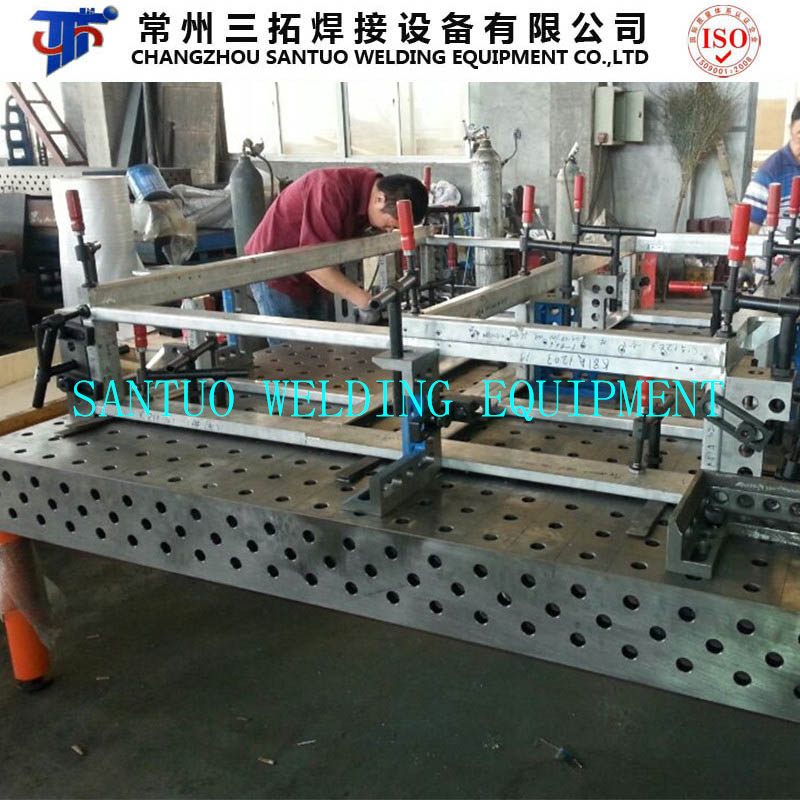

1. Come with five working surfaces, other fixtures and jigs can be installed on it, and also it is expandable in all five directions over the full length, width and weight.

2. Two kinds of material: Steel Welding Table (Q345) or CastingWelding Tables (HT300)

3. System bores diameter: D28 or D16

4. With 100 x 100mm grid pattern of bores for D28 series, and 50 x50mm for D26 series.

5. 3 kinds of Legs for customer’s choice: steel frame, hydrauliclift box or heavy duty wheels

6. Other fixtures and jigs are divided into: Supporting Tools,Locating Tools, Connecting Tools, Clamping and Fixing tools, Locking Tools, andAuxiliary Tools.

7. Economical welding table:

a. Save much cost instead of reserving a lot of complicated andexpensive traditional fixtures

b. Applies to various working conditions without the need of anymodification

c. Safe and convenient to operate

8. Flexible design:

a. can bear extremely heavy loads

b. any work piece can be fixed and clamped on the table with otherfeatures and jigs,

c. 3D welding tables can be linked together against any of itsfive surfaces.

9. Precise design:

a. almost all work pieces can be fixed precisely at certain pointsor surfaces with other fixtures and jigs in the process of assembling orwelding.

b. even imprecise work piece also can be adjusted duringpreliminary work process.

10. Repeatable using:

a. easy to use existing parts in the workshop to imitate workpiece assembly via CAD.

b. Widely applied in the manufacturing and processing of machines

FAQ:

Question 1: when you do the solution for customers, what information needed to be provided from customers?

Answer: Customer need provide picture of the item which need to be soldered, and provide welding procedure and welding position as detailed as you can. Of course, in order to more accurate solution, we hope customer can provide 3D electronic file, it is better with “step” format, or 2D file, and then,Santuo will suggest a solution which need what kind of fixtures and jigs and how many per item to customer, after customer’s confirmation, Santuo can do the quotation for the whole set of solution list.

Question 2: what are daily maintenance for the Welding table, or if any prevention measures?

Answers:

A. If often use, it is better spray splash liquid onto the weldingtable.

B. If not often use, it is better spray anti-rust oil.

C. Usually clean up the welding slag and dust on the table.

D. Don’t arc striking on the welding table and avoid damaging it.

E. Don’t watering on the welding table.

Question 3: what is the difference between casting welding table and steel welding table?

Answers:

A. Casting welding table is a casting mould as a whole, it has a good stability; Steel welding table is soldered forming, stability is inferior to the casting.

B. The casting welding table is heavier than steel and higher cost.

C. For prevent welding slag, casting welding table is better than steel, and also rarely stick welding slag.